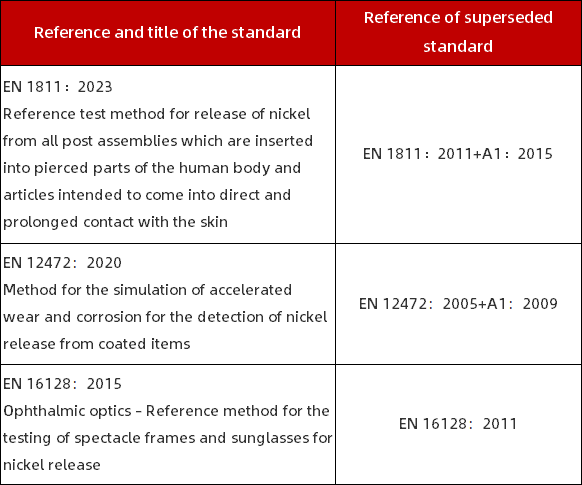

On 20 December 2023, The European Commission has updated the list of harmonised standards for the latest test methods for nickel release in Item 27 of Appendix XVII of the EU REACH Regulation (EC) No 1907/2006. As the following:

The harmonized standard, EN 1811:2011 + A1:2015, is updated to EN 1811:2023. Compared to the previous version, the 2023 version has the following important updates:

1.Change the unit of nickel release to "μg·cm-2·week-1" (micrograms per square centimeter week) (equivalent to the unit of "μg/cm2/week" used in the REACH regulation);

2.Read-to-use solutions of sodium hydroxide and hydrochloric acid are permitted (articles 5.5 and 5.6);

3.Added precautions regarding the use of masking waxes or lacquers: When using wax, immerse the sample in molten wax; When paint is used, 2 to 3 coats of paint may be required (clause 5.9);

4.Added instructions for rinsing samples with test solutions (clause 8.2);

5.Allow the use of filtration to make the release liquid clear: injectable filters can be used to avoid damage to the analytical instrument or clog the capillaries of the instrument (clause 8.2);

6.Specify that when multiple samples of the same article are tested, the amount of nickel released from each sample must meet the migration limit (clause 9.2.2.1);

7.For articles with a migration limit of 0.5μg·cm-2·week-1, the limit of conformity determination of nickel release results is revised from < 0.88μg·cm-2·week-1 to ≤ 0.88μg·cm-2·week-1 (clause 9.2.2.2);

8.The test report requirements have been updated. According to the requirements of the test applicant, the test report can include the sample test area and the test solution volume used (article 10);

9.Delete the requirements for quality control materials (reference test film);

10.Specify that when the presence of nickel in the outer coating is uncertain, two test methods should be used (i.e. EN 1811 combined with wear and corrosion simulation method EN 12472, and without EN 12472) (Appendix B.3);

11.Sample preparation is summarized in tabular form and examples are added. Each individual subcomponent shall meet the limit requirements for nickel release in direct and prolonged contact with the skin. Uniform subcomponent can be obtained by disassembly, cutting or masking (Appendix B);

12.A flowchart of sample preparation and testing procedures for a complete watch has been added (Appendix B.4.2.6).

CTT Reminds:

Jewelry and other metal products companies that export to the EU should pay attention to the updated requirements and make corresponding test changes. CTT has rich experience in product testing, to help you easily understand whether the product safety compliance.